Table of Contents

Introduction

With more vehicles being purchased after the 2008 economic recession in the US, there has been increased congestion and traffic, and the current infrastructure system is aging and deteriorating. The American Society of Civil Engineers approximates that $167 billion and $420 billion is required for highway system expansion and repairs respectively (Wright et al., 2014). The construction and rehabilitation of these systems require considering cost and time, which can be managed through proper planning and scheduling of resources. Additionally, the repetitive nature of the work involved poses a challenge on the resource allocation because it does not always utilize the same quantity over time. Therefore, for smooth progress of the project, an optimized schedule is required for minimizing idle time and cost through efficient utilization of resources.

The main aim of coming up with such projects is to increase the comfort of the environment human access daily. In order for these projects to succeed, a plan must be formed with consideration of cost and time that will be used. The term optimizing schedule means using the available resources to come with the best project within the estimated time at a pocket friendly cost.

Project cost and duration

Construction scheduling is concerned with resource allocation and optimally systematizing activities over time. Construction delays are among the principal problems in construction and have an adverse impact on project success concerning quality. Cost and time as the most critical construction parameters through which, the total cost and total duration of the project are determined in the planning stage. Construction time is the estimated duration that will be required to complete the activity that may be measured in hours, shifts, weeks, months, or even years and is tied directly to the resources applied including number or equipment and crew size. Time estimation is significant to allow calculation of the project completion date and computation of the initiation or termination of a specific activity, as well as enabling resolving of delay claims and enhancing work efficiency.

Construction cost that is the estimated expense for undertaking a project is also a factor that should be considered by a planner. It is constituted of indirect costs such as site overheads and direct costs, which are the expenses that are directly chargeable such as labor and materials and can be identified according to the activities of the project. The findings from a survey by Abdul Rahman and Associates (2013) show that wrong estimation, a long duration between design and implementing, and increasing wages and material prices are the primary causes of construction cost overrun. In overall, for contractors, minimizing project cost maximizes their return on capital because of the reduction in the cost of finance while an earlier completion of the project decreases the risk of labor shortage or inflation. Thus, optimization has been considered essential in construction projects since it is a systematic effort that allows contractors to enhance profit margins and acquire the expected results under given situations.

Scheduling optimization model for repetitive construction projects can be categorized into two primary groups. Models that minimize either project cost or duration while permitting interruptions to work continuity and those models that do not allow crew work disruption. Although these traditional models can optimize only one objective at a time to produce a single solution for the construction project, contemporary scheduling models have been developed that consider both cost and time simultaneously. These models can be categorized as mathematical, heuristic, and metaheuristic.

Mathematical methods

Here the construction problem requires being clearly formulated, which is strenuous for planners with no specified mathematical knowledge. In addition, it is a time-consuming task. Since the contractor needs to search algorithms and processes that can ensure that, the constraints are fulfilled. Optimizing process creates an environment for projects to be done under controlled parameters.natually; people have the desire of producing more goods of high quality at the lowest cost. In optimization, an individual or a company can constrain the cost and the quality and maximize the quantity or constrain the quality and quantity and minimize the cost. In mathematical method it is important to consider the health and be wealthy than being ill and poor.

Critical Path Method

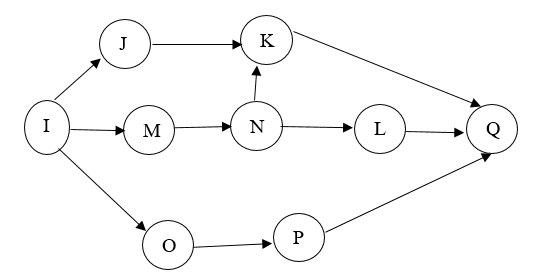

It is one of the most utilized project-scheduling algorithm because it can be applied to any project with interdependent activities. The CP model involves certain items in its implementation including a detail of activities within the project; the primary connection between the activities; the duration of each activity, which can be utilized in computing the longest path to finish the project as well as the latest and earliest starting, and termination time of each of activity. Diagram 1 indicates an example of a CPM network structure showing the critical activities M, N, and L that are on the critical path I-M-N-L-Q whose delay may cause overall delay to the entire project. The float activities J, K, O, and P that are the activities not on the critical path, which can be delayed without effect on the project’s duration.

Diagram 1: Example of a CPM network

The main restriction of CPM schedule is its dependency constraints and the high reliance on time. A two-phase approach was proposed to manage the limitation whereby the precedence connections are described in the first stage while resources are introduced in the second phase using leveling algorithms or resource allocation. Although some analysts argue that resources should be omitted in the initial stage, most concur that lack of considering resources would hinder the development of practical construction activities. Furthermore, it is mostly strenuous to differentiate between resource and technological constraints. Lu and Li (2003) introduced a method that offers a more robust model of planning that exploits improved computer technologies to address such difficulties known as “A Construction Planner’ (ACP), which clearly describes all constraints simultaneously.

The Resource-Activity-Critical-Path Method accommodates repetitive scheduling and resources constraints. It defines floats, the start and finish times, and the combined precedence relationship between resource and technology as activity attributes. Nevertheless, the method does not consider the overall cost of the project; thus, Lu and Li (2003) enhanced their approach to managing this issue, which in addition to the commonly utilized minimum distance and duration constraints, the updated method considers maximum distance and time constraints. The proposed approach accounts for all linear activities that are classified into four groups according to their abilities and essential status to affect the overall project time.

Dynamic programming

It is useful for handling complex and overlapping issues that can be divided into sub-categories of problems. Zhou and Colleagues (2013) presented a model that incorporated the cost and time variable into the optimization procedure. The approach determines the solution with two phases including the backward process that includes scanning and choosing processes that guarantee a certain minimum condition is achieved. In addition, the forward process that entails a cost-time trade-off evaluation to ascertain certain minimum circumstances is engaged. Nevertheless, developing constraints and objective functions is difficult and time-consuming. Moreover, few planners possess the needed mathematical knowledge to execute such a development; therefore, its application to project scheduling of construction projects has been restricted.

Linear programming (LP) and integer programming (IP)

They are analytical algorithms applied to manage the construction scheduling and optimization problems. According to Bazaar, Jarvis, and Serial (2011), LP solves issues with linear objective functions dependent upon linear inequality and equality constraints. The LP method can be represented by the following formula: Minimize cTx subject to Ax≤b and x≥0. The aim is to reduce or increase the linear objective function subject to the constraints. However, if the variables are limited to be integers, the LP issue is altered to an IP problem expressed in a similar formula but with the xi integer where i= 1…,n. Two approaches can be applied when solving linear programming models including the simplex method that can solve problems without a limit of decision variables while the graphical method can only tackle problems with two decision variables.

Substantial attention has been afforded to these mathematical approaches to scheduling because of their inherent accuracy and efficiency. Besides, linear programming can be used to solve a variety of problems such as the location of new production plants and offices, ascertaining the optimum size of the project, personnel assignment, routing and transportation issues, and optimizing utilization of resources. Luathep and Partners (2011) formulated an integer LP method to address the cost problem using the resource leveling technique in a highway construction project. The activity and rate floats are presented subject to the resource utilization of an individual activity whereby rate float is demonstrated to be effective in attain better resource utilization if the activities engage shared resource.

The benefit of the integer LP method is the applicability on repetitive activities, but the chief demerit is that the calculation burden may increase exponentially with the expansion of the problem size. Besides, this approach does not cover the maximization of production due to its single objective orientation of leveling the resources. Overcoming this sole objective limitation Luathep and Partners (2011) evaluate a hybrid optimization method that incorporates IP and LP allocating planners with a convenient way of evaluating the cost-time trade-off problem. The approach is implemented in two phases; first, the LP is used to produce a lesser limit of the minimum direct curve, and then the IP is utilized to locate the precise solutions.

Heuristic methods

Though mathematic approaches guarantee the provision of an optimum solution to the construction problem, the time consumed and the difficulty level makes them inapplicable in many cases. Thus, planners often employ the heuristic methods where the process speed is as critical as the reliability of the solution. This approach is based on past experiences to solve real-time optimization problems and has several benefits including providing acceptable solutions of difficult issues in possible time and is more flexible than mathematical approaches, enabling the inclusion of conditions that are arduous to model. However, the major shortcoming is that the method does not guarantee the best solution in all situations.

Zhou and Colleagues (2013) suggests that a proper heuristic algorithm should ensure that a solution could be acquired with moderate computational effort, there is a high probability the solution is near optimal, and the potential for receiving a bad solution is small. There are two broad categories of heuristic algorithm, namely, constructive algorithms and local search algorithms. Constructive heuristic also referred as greedy algorithms always initiate from a clear solution and develop a complete solution through continuously assigning values one at a time to decision variables. It is easy to comprehend and is straightforward and fast to implement. However, the solution quality is highly reliant on problem occurrence; thus, it is difficult to develop a robust algorithm for all problem cases.

Unlike constructive heuristic, local search also known as iterative algorithm initiates with a feasible solution to the problem and efforts in continuously enhancing it. The method entails exploring the neighborhood of the current solution in each step of the procedure and replacing it with another that has better value. The local search process ends when all neighbors have inferior value to the current situation. This method obtains good solutions quickly; nevertheless, it is limited to the local optima whereby a project may possess better value than all the neighbors may but does not represent the best potential solution. Various techniques depending on choice and termination criteria have been proposed over the years to improve the efficiency of local search through surpassing the boundaries of the local optimum. They include guided local search (GLS), tabu search (TS), and simulated annealing (SA).

Siemens (1971) introduced an algorithm that can decrease the project time when its anticipated duration surpasses an established limit. The approach can ascertain the activity that can be eliminated and by what amount allowing the minimization of the project duration at a reduced cost. On the other hand, the structural model illuminates the network flow formulation, whereby the advancement and activities of a project are represented as incidents and jobs, respectively. It is presumed that the crash and normal completion duration are known with an algorithm being allocated for the optimization computation.

A heuristic approach for optimizing multiple projects based on cash constraints was proposed. The approach establishes the schedules for all potential activities and ascertains the finance accessible for the project duration as well as that required for each schedule. Within the schedules, the effect of activities on the available cash is evaluated as well as the influence of the schedules on the overall’s project time. Collation between the IP and the proposed heuristic method on a project indicate that the optimum solutions are proportionate to the solutions acquired utilizing the proposed model. This method is easy to incorporate into management software allowing fast computation of solutions. Nevertheless, the disadvantage of this heuristic method is that the calculation effort expands tremendously as the duration and the number of activities increase.

Meisel and Bierwirth (2009) developed a heuristic method but focuses on the resource constraints. These approach groups activities based on potential combinations into classifications and organizes all the activities in the chosen category to reduce the project time. The permutation tree-based technique is applied to establish the substitute activity combinations and identifies the one resulting in the smallest growth in project growth. This heuristic method may decrease the indirect costs through reducing the project duration; nevertheless, it may also raise the overall cost or the direct costs. Another heuristic resource scheduling method considers multi-skilled resources. This method enhances the resource substitution approach through collecting and evaluating information on resources that can be exchanged. As such, resources exploited on a low level can be substituted with limited resources in the scarcity duration for the minimization o the project duration and cost.

Unlike the mathematical models that demand substantial computational effort and are often integrated into computers, Heuristic methods are simple and can be calculated utilizing manual techniques. These characteristics are the primary reasons why heuristic methods are extensively employed to solve construction scheduling and optimization. However, this method does not allocate a variety of potential solutions allowing the planner to select the most appropriate based on the different construction circumstances. Furthermore, a majority of heuristic methods can only optimize a single objective, and they are problem reliant, thus, presenting a challenge for their further application in other projects.

Metaheuristic methods

These approaches are utilized for addressing optimization problems through combining intelligently distinct concepts for exploiting and exploring the search space to find near-optimal solutions. Most favored metaheuristic methods have been formed from natural behaviors, and their aim is to imitate natural activities to guarantee optimal solutions.

Genetic Algorithm (GA)

They are techniques that are used to tackle both single and multi-objective optimization problems. The creation of a GA problem entails producing multiple potential solutions for the issue; then the logical solutions are integrated to create new solutions to the following iteration. GA evolved from a certain category of evolutionary algorithms and employed to calculate near optimal solutions. Darwin’s theory of evolution inspires GA, which adopts the structured exchange of genetics substances and the survival of the fittest among the population members over following generations as a system for the search procedure. As a result, the approach is executed in three main stages. First, the initialization step that produces an initial series of potential solutions for the resource usage issue. Second, the fitness analysis stage whereby the computation of the quality, duration, and cost of each produced solution is performed. Third, the population generations phase that strives to enhance the fitness of solutions over successive generations (Long & Ohsato, 2009).

The GA incorporates reasonable solutions to a linear chain known as a chromosome whose genes are constituted by real numbers or integers. After the initial population is selected randomly, the fitness of solutions is examined through the objective function thereby allocating each solution distinct fitness magnitudes, which constitute the probability of selection into succeeding generation. Subsequently, through the process of genetic activities to create progenies, the chosen parent chromosomes experience stochastic transformations. There are two forms of transformation: the mutation that develops new characters through undertaking an instant alteration in an individual parent, and crossover, which generates new individuals through interchanging components of information at unsystematically chosen crossing point from both parents. Then, the new individuals are analyzed, and those with better fitness values form the parenting populace for the following generation. The algorithm converges to the superior solution after the succession of multiple generations, which is presumed to constitute the optimal solution to the problem. Therefore, the GA is a random but still an efficient parallel searching algorithm that can synthesize information from the searching space to acquire a globally optimal solution.

Because of the incompetence of the mathematical programming and heuristic approaches for solving complex projects. Liao and Associates (2011) evaluates a multi-objective computational optimal method for the large-scale CSO network problems, which integrates the resource leveling, resource limit, and the time-cost trade-off models. An enhanced mutation operation was presented to regulate the crashing time; while the improved mutation guarantees that the progenies are practical solutions. However, because of its random nature, a substantial quantity of computational time is needed. Furthermore, traditional GA-based models for addressing problems with the project’s cost and duration are subject to restrictions because the model only handles the time-cost relationship and the formulation of the objective function is performed manually.

In the implementation, the actual cost and duration for each activity in construction projects are highly uncertain, which makes it strenuous for managers to form a decision. Prevailing over this challenge an optimization method was proposed for addressing the trade-off problem of construction duration and cost with uncertainties. The instituted fuzzy theory allocated the project cost and duration with fuzzy digits, and then the GA was employed to tackle the optimization problem. Since quality is an essential component of construction operations and outcomes, it can be incorporated into a GA-based approach whereby the purpose of the optimization problem shall be to maximize quality while minimizing cost and time.

We can do it today.

Particle Swarm Optimization (PSO)

The PSO that is based on swarm behavior discerned in nature including bird and fish schooling. The model searches the space of an objective function by calibrating the routes of independent instruments, known as particles. Dr. Kennedy and Dr. Eberhart developed this technique in 1995 after observing the social behavior of fish schooling and birds flocking. The technique has similarities with general algorithm in that it searches for optima by updating generations. Particle swarm optimization lacks evolution operators like mutation and crossover. According to this technique, each particle keeps track of its path in the problem space. This method is attractive because it has a wide range of applications that can be specific to a certain project. Each particle follows a route that can be reproduced at a time-reliant positional vector. As a metaheuristic method, this approach can search a wider space for the possible solutions and requires little or no assumptions about the problem to be addressed, which deems it effective for handling the combinatorial optimization problems.

The motion of swarming particles includes two primary elements: a deterministic component and a stochastic element. The movement is random towards the location of the existing global best, and when a particle discovers a position that is better than the preceding ones, it identifies this position as the contemporary best for the particle. Rini, Shamsuddin, and Yuhaniz (2011) proposed a PSO-based method to address the resource-restricted project-scheduling problem with the purpose of reducing the project time. To avoid the infeasible progression from existing particle locations, a particle representation approach of activities precedence was incorporated. Afterward, a parallel method was employed to decipher the particles to a reasonable schedule based on the resource and priority constraints. Nevertheless, in this study only the project duration was covered assuming an equally significant factor, that is, time.

Although the solution derived by PSO may not be a local or global optimum, it is a useful algorithm for addressing the combinatorial optimization problems. However, when populace variety decreases, the particle speed will reduce resulting in the minimization of the capacity of the approach for searching reasonable solutions.

Conclusion

The construction scheduling and optimization have been evaluated using various algorithms and methods, which consider the important construction parameters, that is, cost and time. The traditional single objective optimization problems have been improved to multi-objective focusing on several construction constraints. Time estimation is significant to allow calculation of the project completion date and computation of the initiation or termination of a specific activity, as well as enabling resolving of delay claims and enhancing work efficiency. Multiple approaches have been employed to solve optimization problems and can be classified into three groups: metaheuristic, heuristic, and mathematical methods. Mathematical methods require planners to have an analytical background and offer an optimum solution; however, it is a time-consuming task. Example of a mathematical method is the critical path method. The critical path model involves certain items in its implementation including a detail of activities within the project; the primary connection between the activities; the duration of each activity, which can be utilized in computing the longest path to finish the project as well as the latest and earliest starting, and termination time of each of activity.

The heuristic methods are easy to comprehend and fast to implement; nevertheless, they are problem reliant making them inefficient to be engaged in other projects. Heuristic algorithm should ensure that a solution could be acquired with moderate computational effort, there is a high probability the solution is near optimal, and the potential for receiving a bad solution is small. There are two broad categories of heuristic algorithm, namely, constructive algorithms and local search algorithms. Finally, the metaheuristic methods can address optimization problems through imitating natural processes, and the GA is the most applied approach.

The general algorithm came from a certain category of evolutionary algorithms and employed to calculate near optimal solutions. The algorithm was inspired by Charles Darwin’s theory of evolution that adopts the structured exchange of genetics substances and the survival of the fittest among the population members over following generations as a system for the search procedure.

- Wright, J., Garrett, J.K., Hill, C.J., Krueger, G.D., Evans, J.H., Andrews, S., Wilson, C.K., Rajbhandari, R. and Burkhard, B., (2014). National connected vehicle field infrastructure footprint analysis (No. FHWA-JPO-14-125).

- Abdul Rahman, I., Memon, A. H., Karim, A., & Tarmizi, A. (2013). Significant factors causing cost overruns in large construction projects in Malaysia. Journal of Applied Science, 13(2), 286-293.

- Zhou, J., Love, P. E., Wang, X., Teo, K. L., & Irani, Z. (2013). A review of methods and algorithms for optimizing construction scheduling. Journal of the Operational Research Society, 64(8), 1091-1105.

- Long, L. D., & Ohsato, A. (2009). A genetic algorithm-based method for scheduling repetitive construction projects. Automation in Construction, 18(4), 499-511.

- Liao, T. W., Egbelu, P. J., Sarker, B. R., & Leu, S. S. (2011). Metaheuristics for project and construction management–A state-of-the-art review. Automation in construction, 20(5), 491-505.

- Lu, M., & Li, H. (2003). Resource-activity critical-path method for construction planning. Journal of construction engineering and management, 129(4), 412-420.

- Siemens, N. (1971). A simple CPM time-cost tradeoff algorithm. Mgmt. Sci., 17 (6). B-354-363.

- Bazaar, M. S., Jarvis, J. J., & Serial, H. D. (2011). Linear programming and network flows. John Wiley & Sons

- Luathep, P., Sumalee, A., Lam, W. H., Li, Z. C., & Lo, H. K. (2011). Global optimization method for mixed transportation network design problem: a mixed-integer linear programming approach. Transportation Research Part B: Methodological, 45(5), 808- 827.

- Meisel, F., & Bierwirth, C. (2009). Heuristics for the integration of crane productivity in the berth allocation problem. Transportation Research Part E: Logistics and Transportation Review, 45(1), 196-209.

- Rini, D. P., Shamsuddin, S. M., & Yuhaniz, S. S. (2011). Particle swarm optimization: technique, system and challenges. International Journal of Computer Applications, 14(1), 19-26.