Table of Contents

Abstract

Global warming has been a major global issue with researchers and other stakeholders developing new solutions to tackle the high level of greenhouse gases emission .Burning of fossil fuels which are mainly issue din many engineering sector has been identified as the key contributor to emission of CO2 into the atmosphere, mitigation measures such as the production of renewable energy sources such as methane an ethanol has provided a reliable and affordable solution to partially tackle the problem. Ethanol and methanol provide suitable sources for green energy, which is the key focus for environmentalists worldwide. The future of biological energy production remains promising, however research needs to be carried out to evaluate the processes of production as well as the impacts these elements have on the environment. The overall efficiency and economics of using these products as alternative energy sources are some of the key issues that need to be addressed in the evaluation.

Introduction

This research focuses on ethanol and methane as sustainable and economic friendly biofuels that are being used in the engineering industry. An analysis of the production process is carried out to determine their efficiency compared with the production of traditional fuels. The current and future demand for fuels cannot be met by the traditional fossil fuels that the world has been relying on. With the need to conserve the future by providing alternative and reliable energy sources. The engineering and construction industry has been a key consumer of the different fuels produced hence the need for research on how to integrate green energy in the industry. Future construction and engineering practices will be based on sustainable and economic technology .As economical, technological, other social issues continue influencing the engineering, and construction world, the provision of sustainable solutions is inevitable. Biotechnology has provided sustainable solutions towards solving some of the challenges faced in the engineering and construction industry.

Engineering and biotechnology are key areas that have contributed towards the production of biofuels and sustainable future solutions towards he provision of green energy. Methane, ethanol, and the leading products in biotechnology research aimed towards production of biofuels with focus mainly being on biodiesel production. Environmental factors are not the only issues influencing the use of biofuels, economic factors as the world seeks for renewable and affordable energy sources have also contributed to the research for alternative energy. Geopolitical factors have also played a role with nations seeking to provide sustainable energy to their citizens.

Fossil fuels have traditionally been used as the sources of energy ,however fossil fuels deposit are slowly diminishing ,capital and technology investment required to exploits these fuels is high for some countries to independently carry out the exploitation .Countries that lack fossil fuels supplies have to invest highly in fuel purchase which has resulted to economic challenges. The economic effects are felt in different sectors of the economy including the engineering and construction sector which heavily relies on petroleum products extracted from fossil fuels (Barbaro & Bianchini, 2009).

The production of ethanol and methane is mainly done from organic materials, most of the production is being carried out by the recycling of waste products .Sugarcane and corn have been widely in the organic production of ethanol. Methanol can be made from biomass which is readily available from any organic waste. The lignocellulosic materials from waste organic products are broken down into simple sugars in different processes to obtain ethanol, methane and other biofuels. This provides a sustainable and economical process of obtaining green fuels compared to the production and use of fossil fuels.

Various considerations have to be out in place during the production of methane and ethanol, there are various complex processes involved that have to be carried out under specific conditions. These processes influence the construction of any production plants with environmental issues being of key focus. The design elements in the construction of a production plant are discussed further in the report.

Literature Review

In this section an in-depth review and analysis of previous study carried out in the production of biofuels mainly ethanol and methane is carried out.

Ethanol Production

Ethanol production involves the catalytic hydration of ethelyne.The other production processes include the fermentation of sugars from lignocellulosic materials.

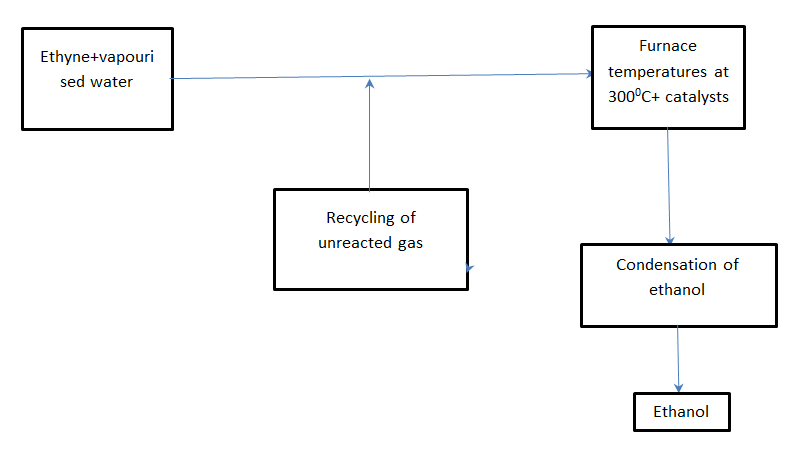

Ethanol Production from Ethylene

The production processes involves the direct or indirect hydration of ethylene. The ethylene which is combined with water is heated in a furnace at a suitable temperature of 300oC.The mixture is then passed under a catalytic reactor under high pressure with phosphoric acid being the main catalysts in this process (Method and system for ethanol production, 1981). This process produces acetaldehyde as the main by product, which is further reacted with water to produce ethanol. Figure 2.1 shows the diagram flow scheme used in the production process.

The chemical equation for the reaction is shown below;

CH2 (g) +H20 (g) CH3CH2OH (g)

The maintenance of high pressure and temperature is suitable in ethanol production with a higher conversion rate being achieved under suitable pressure and temperature conditions.

Ethanol Production from Lignocellulosic Materials

The use of organic products such as agricultural crops has resulted to the production of ethanol. The plants contain lignin, cellulose and hemicellulose which are the key products needed to produce ethanol. The processes involved in the production of ethanol from these materials include pretreatment, hydrolysis, fermentation distillation. The hydrolysis processes breaks down the sugars in the organic materials that are fermented to form ethanol. The complex cellulose and hemicellulose sugars are broken down to enable the enzyme action during fermentation .Once fermentation has taken place, purification is carried out to remove any impurities (Barbaro & Bianchini, 2009) . Distillation is the main purification processes. Diagram 2.1 shows the flow processes in the production of ethanol from lignocellulosic materials.

This production process is expensive and involves the use of complex technology compared to other methods of ethanol production. The design of the production plan is compel since it requires more digesters and other facilities. The fermentation process requires regular monitoring to ensure optimal performance of the microorganism needed for the fermentation process to take place (Sugar-Based Ethanol Biorefinery, 2009).

Production of Ethanol from starch and simple sugars

This method is carried out to produce first generation bioethanol obtained from the fermentation of simple sugars obtained from organic materials. Previous research shows that sugarcane provides a suitable organic material for ethanol production. Research has also been carried out to identify plants, which can be used to produce ethanol through the hydrolysis process with starch feedstock being the main plants used for the production of industrial ethanol in a wet milling process.

Methane production from organic solid waste.

The anaerobic digestion of solid waste from plants and animals is used in the production of methane .Anaerobic bacteria is used to provide suitable fermentation parameters for the gas to be produced. The quantity of methane produced depends on the size of the digester and provision of suitable temperature and PH conditions (Methanol production method and system, 1984).

Operation Principles in Methane and Ethanol Production

The production of methane gas is carried out under an anaerobic respiration process. Various conditions have to be met for the digestion process to be effective. There should be no leakage in the digester for safety purpose. During production, temperatures have to be regular checked to ensure optimal production. When using methane gas for domestic or industrial purpose, the pump, and pipeline system should be checked for any leakages.

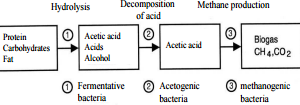

Diagram 2.3 shows the fermentation principles in the production of methane.

The first stage is the hydrolysis process where the hydrocarbons are broken down into simple monomers, fatty acids, saccharides, and amino acids. The fermentative bacterium provides a favorable environment for the hydrolysis process to take place. The acetogenic bacteria used in step two breaks down the complex organic molecules that remained in the first stage .Acetic acid is produced during this stage and is further converted into methane gas by the methenogenic bacteria.

In ethanol production there are various thermochemical processes involved, the fermentation processes is influenced by the nature of the organic materials used as well as environmental factors such as temperature. In the production of ethanol pressure is a key factor, if pressure is not maintained at the required levels the production is likely, pressure is controlled by use of pressure gauges. The temperatures must also be favorable for enzyme action to take place.

Tests to determine the efficiency of the products such as starch that are used in the production of the fuels need to be carried out .Samples are selected from each production batch.

Construction Methods in the construction of methane and ethanol production plants

During the construction of ethanol and methane production plants, various considerations have to be made .The size of the plant is determined by the production volume that is required .When there is a higher volume to be produced a bugger plant has to be set up. Either production can be classified as large scale or small-scale production based on the demand .Control measures must also be put in place to ensure safety while handling the products .Methane gas is highly flammable hence, the need for suitable control measures to avoid any leakages during the construction.

During the construction works, hydrolysis tanks of appropriate size need to be provided. A functional heating and cooling with the right control devices needs to be provided. During design and construction, construction economy has to be considered to ensure the facility fits within the proposed budget.

Environmental control parameter during construction

During environmental control, all the environmental risks have to be identified as well as the mitigation measures that need to be put in place. Water and air pollution has to be avoided during construction. Emission testing has to be done before the relevant authorities approve a production plant. Emission limits that are allowed vary based on the location of the plant; however, mitigation measures must be put in place to control the emissions .Before the approval for the production plant has been made, and quality control measures must be clearly identified. Any waste products should be well disposed without having any negative effects on the nearby environment .The safety of those around the production plant and those working in the plant need to be safeguarded at all times. Production facilities for industrial production of methane and ethanol need to be located away from residential areas to avoid accident and other risks that might occur in case of a gas leakage or any other system failure.The construction guideline is subject to change based on the policies governing construction in the region where a production plant is being set up.

Future trends

The future growth of any country will be determined by how well a country is able to integrate technology in the production of new fuels. Currently nations have shifted to wind and solar energy as alternative sources of green energy. Focusing on green energy is the key to economic success for any nation, however the shift towards green energy need to be based on reliable and sustainable energy sources. The energy solution identified need to focus on providing long-term solution to the global energy and environmental crisis.

With the increased energy demand for domestic and industrial use, there is need to tap into other form of fuels for future use. The global consumption of natural gas and mineral oils is occurring at a higher rate that the rate at which those gases and oils were formed with their production taking a downward trend due to the exhaustion of the existing gas and oil deposits. The shortage in natural oil and gas deposits has resulted to research into other form of sustainable and environmental friendly fuels. Although green power seems to be the solution to the challenges being faced, it is a cheap option; the necessary infrastructure has to be provided for a country to effectively rely on green energy.

The transportation industry has now identified bioethanol as a suitable replacement for petroleum based fuels. However, there is need to focus on the use of other crops rather than edible crops to produce the fuel. The food supply is not enough for human consumption as well as ethanol production. There is need to focus on the production of ethanol from waste organic products or using non-edible plants to produce the biofuel.

Future trends in the production of ethanol and methane will focus on the sustainability, cost as well providing better approaches towards green energy. Searchers in the past have not been able to provide consistent data on the comparison between carbon emissions from different biofuels, however it is clear that the emissions are lower compared to emissions from traditional fuels. Innovation has now made it easier for homesteads to engage in the production of methane gas for home use. There are still challenges to homestead production of methane gas for cooking and lighting purpose with safety and cost of production being a challenge to main especially in developing countries. Continued research and study in this area will provide better solution towards handling the current challenges.

Use of sensing technology and automation in the production process is slowly taking place and will eventually be fully adapted in the production of methane, ethanol, and other biofuels. This will provide a suitable solution to risks that might occur due to leakage in production as well as cut the system maintenance cost.

Currently biofuels such as ethanol are not being independently used, they have to be combined with traditional fuels for them to perform effectively, and this is a major challenge towards the full adoption of biofuels. Future research will focus on the improvement of the biofuel for them to be used independently as well as reduction of carbon emission during their production and use.

Countries will focus more on production of green energy hence the demand for better and more complex production design will be on the rise .Production plants will have to handle the increased capacity without having to compromise on efficiency and security, designers will be required to develop complex machine and facilities for industrial use as well as simply the existing designs for domestic use.

Advantages and disadvantages of methane and ethanol

Advantages

- The cost of biofuels is relatively lower compared to the cost of fossil fuels. This benefit is felt at a household and national with many households shifting to production of methane gas for cooking and lighting .Ethanol has provided an alternative biofuel being used in the transport industry.

- The biofuels can be manufactured from a wide range of materials, which cannot be exhausted unlike fossil fuels, which are getting scarce as the demand for fuel gets higher.

- Methane, ethanol, and other biodiesels are environmental friendly. There is reduction in carbon emission with many nations now shifting on green energy; methane and ethanol offer a suitable solution.

- A country that relies on methane and ethanol for its energy purpose is less dependent on other nations for funding as well as oil provision. Many countries are spending a lot of money on oil importation since they cannot be able to produce it, having an alternative energy would be a financial advantage to a country.

- Methane and ethanol offer a renewable form of energy, which can be relied on for future energy needs and increased energy demands.

Disadvantages

There is high production cost for setting up the production plant as well as maintenance cost of the production facilities.

- Production of methane and ethanol poses a challenge to food security since edible crops are used in production, the food shortage can also result to increased food prices.

- Production of these fuels requires a large amount of water; this can result to lack of adequate water for irrigation and human consumption.

- Production and use of methane and ethanol causes carbon emission that result to global warming.

Conclusion

In conclusion, ethanol and methane provide a sustainable solution towards the energy crisis that the world is currently facing. However, there is need to carry out more research on the production of the fuels. The production of biofuels is a complex process, using technology to simplify the process and providing solutions that re reliable on a home level would be a major stepping-stone towards green energy production. Biofuels provide a promising solution to the energy crisis but there is need to integrate biofuels with other energy sources. Use of the appropriate technology in bioengineering and research will provide more solutions to the energy problem.

The report has covered the basics processes featured in the production of ethanol and methane. An analysis of the production processes has also been featured with various construction requirements being discussed. A comparison of fossil fuels and biofuels such as methane and ethanol shows that there are varying levels in carbon emissions, research on how to further reduce carbon emission in the process of producing and using the biofuels would encourage further use of ethanol and methane for domestic and industrial purpose.

- Barbaro, P., & Bianchini, C. (2009). Catalysis for sustainable energy production. Weinheim: Wiley-VCH.

- Methanol production method and system. (1984). Argonne, Ill.

- Sugar-Based Ethanol Biorefinery. (2009). Golden, Colo.

- Methanol production method and system. (1981). Argonne, Ill.