- Dole, C. E., Lewis Jr, J. E., Badick, J. R., & Johnson, B. A. (2016). Flight theory and aerodynamics: a practical guide for operational safety. John Wiley & Sons.

- Halliwell, I. (2001). Exoskeletal engine concept (1st ed.). [Cleveland, Ohio]: National Aeronautics and Space Administration, Glenn Research Center.

- Mohan, S. (2014). Apache Solr High Performance (1st ed.). Birmingham: Packt Publishing.

- Santoro, R. & Pal, S. (2003). Thrust augmentation measurements using a pulse detonation engine ejector (1st ed.). [Cleveland, Ohio]: National Aeronautics and Space Administration, Glenn Research Center.

- Senft, J. (2007). Mechanical efficiency of heat engines (1st ed.). Cambridge: Cambridge University Press.

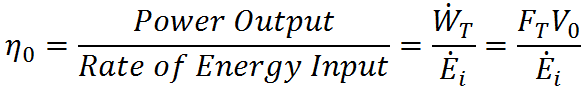

Performance and Efficiency in Thrust-Producing Engines

| Subject: | Science |

| Type: | Expository Essay |

| Pages: | 2 |

| Word count: | 438 |

| Topics: | Scientific Method, Engineering, Physics |

Sources

More samples

Related Essays

Get a brand-new guide on essay writing

The download will start within seconds. Good luck!

Download Sample

This essay is publicly available.

Offered for reference purposes only.

Offered for reference purposes only.

By clicking Get this Sample you agree to the Terms And conditions and Privacy policy.

Thank you!

The download will start shortly.